If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

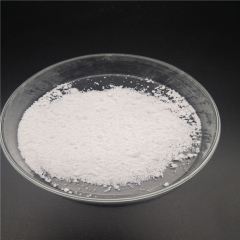

Aluminum oxide, known chemically as Al2O3, is an industrial material used in refractories, ceramics, polishing and abrasive applications. The annual world production is about 115 million tonnes. Over 90% of this is consumed for the manufacture of aluminium metal. The remainder, normally termed speciality alumina is used in a variety of applications that reflect the inertness and excellent wear resistance characteristics of the compound as well as its good thermal and electrical resistance properties.

The chemical bonding between aluminium and oxygen in the molecule of aluminium oxide is ionic, however it also shows some degree of covalency. This is due to the relative difference in electronegativity between the group 13 aluminium and the group 16 oxygen atoms. The aluminium atoms have three electrons in their valence shell and are therefore less electronegative than the oxygen atoms which have six electrons in their valence shell. This means that when the aluminium atoms come close to the oxygen atoms they donate their excess electrons to them. The two oxygen atoms therefore gain a +3 charge (shown as 3+) and the three aluminium ions acquire a -2 charge (shown as -2+).

For adhesive bonding of rolled or extruded aluminium alloys to other materials it is usual to pre-treat the surface by grinding, acid washing, spray coating etc. However for castings it is sometimes difficult to obtain durable adhesive bonds even after pre-treatment. This is because the surfaces of castings may contain a variety of contaminant species such as graphite powder, oxides and silicon.