If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

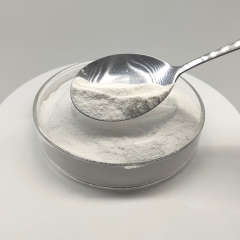

The combination of chromium oxide plus aluminium oxide is one of the most important catalyst systems in oxidative conversion of paraffinic hydrocarbons. The synthesis of this catalytic system was described by Eischens and Selwood in the early 1930s, and has since been a subject of considerable interest.

Several studies have shown that the catalytic activity and magnetic susceptibility of this catalytic system decreases with increasing chromium oxide content. The optimum concentration is about 20% Cr2O3 in alumina. This is considered the region of maximum activity and also of greatest sensitivity to the amount of hydrogen injected into the reaction.

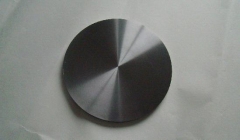

Chromium oxide is a well known catalyst for the oxidation of chlorinated hydrocarbons in a range of applications, including the gasification of biomass and coal. However, it is prone to evaporation during the course of the reaction, which may result in irreversible deactivation of the catalyst system.

Aluminium oxide is widely used in the metallurgical, chemical and ceramic industries. It is a refractory material, with outstanding thermal stability and wear resistance. It is also a common ingredient in glass, ceramic and enamel coatings. It is also a fire retardant and smoke suppressant.

It has a close-packed, hexagonal structure that is analogous to the crystalline alumina found in nature. It is derived from the reduction-oxidation (redox) reaction of sodium dichromate with sulfur at elevated temperatures.

Various combinations of chromium oxide and alumina are used in refractories and other high-temperature materials. The refractory additives are manufactured via a variety of bonding and forming techniques.