If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Magnesium Aluminum Boron Alloy is an advanced alloy that combines high strength, low density and excellent corrosion resistance. Due to its unique properties, magnesium-aluminum alloys are widely used in aerospace, automotive, electronics and defense fields. This article will delve into the definition and characteristics of magnesium-aluminum alloys and how to improve their performance while also analyzing their sustainability and market competitiveness.

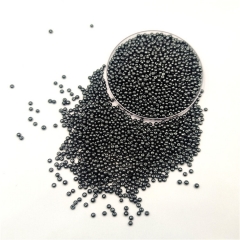

Magnesium Aluminum Boron Alloy Definition and Characteristics

Magnesium-aluminum alloy is formed by adding aluminum and boron elements based on magnesium. Its characteristics mainly include high strength, low density, excellent corrosion resistance and easy processing and shaping. The strength of magnesium-aluminum alloy is higher than that of pure magnesium. At the same time, the density is lower than that of pure magnesium, which makes magnesium-aluminum alloy an ideal lightweight material. In addition, magnesium-aluminum alloy has better corrosion resistance than other metal materials and can maintain its physical properties for a long time.Improve the performance of Magnesium Aluminum Boron Alloy

Researchers have conducted a lot of research to improve the performance of magnesium-aluminum alloys further. Here are several effective performance improvement strategies:- Optimize alloy composition: By adjusting the contents of aluminum and boron, the mechanical properties and physical properties of magnesium-aluminum alloys can be changed. Research shows that as the aluminum content increases, the strength and hardness of magnesium-aluminum alloys increase, while as the boron content increases, their corrosion resistance improves.

- Heat treatment: Heat treatment can change the grain size and distribution of magnesium-aluminum alloy, improving its mechanical properties. Research shows that the strength and toughness of magnesium-aluminum alloys can be significantly improved after proper heat treatment.

- Alloy strengthening: By introducing nano-scale particles or fiber reinforcements, the strength and toughness of magnesium-aluminum alloys can be significantly improved. For example, adding nano-sized silicon carbide particles to magnesium-aluminum alloys can significantly increase their hardness.

(Magnesium Aluminum Boron Alloy)

The sustainability of Magnesium Aluminum Boron Alloy is mainly reflected in the following aspects:

- Resource saving: Magnesium Aluminum Boron Alloy is a resource-saving material. Due to its low density and high strength, it can achieve better results with less material consumption. During the production process, its energy consumption is also relatively low, which meets the requirements of energy conservation and emission reduction.

- Energy saving: Magnesium Aluminum Boron Alloy can reduce energy consumption during transportation and logistics due to its lightweight properties. Applications in automobiles, aerospace and other fields help reduce fuel consumption and carbon emissions.

- Environmental protection: Magnesium Aluminum Boron Alloy is an environmentally friendly material that does not produce harmful substances during the production process. Its recycling rate is high, which can reduce waste generation and environmental pollution.

- Recycling: Magnesium Aluminum Boron Alloy has good recyclability and can be recycled and reused many times. This not only improves resource utilization but also reduces environmental pollution.

- Adapt to future development: As people pay more attention to environmental protection and sustainable development, Magnesium Aluminum Boron Alloy, as a sustainable material, will adapt to the needs of future development and has broad application prospects.

(Magnesium Aluminum Boron Alloy)