If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

For several materials, aluminum oxide is the preferred alternative to silicon carbide. The two types are effective on various surfaces and can be used together to produce a finer abrasive effect.

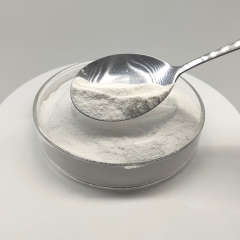

Aluminum oxide is available in three forms: brown, pink and white. Brown is the most common type. It is cheaper than pink and offers longer life. Pink is more similar to silicon carbide, which breaks down at a faster rate.

Silicon carbide is not as tough as aluminum oxide. This makes it more brittle and less durable. In addition, it has a narrow shape and is not as sharp as aluminum oxide. However, it is more versatile.

While both silicon carbide and aluminum oxide are effective on various surfaces, it is best to choose a combination that will allow you to get the best results. Some of the more common applications include cutting wood, plastic, fiberglass and glass.

Both materials can be used to cut metals. They are also good for cleaning and polishing glass and metals. When you are considering whether to use aluminum oxide or silicon carbide, remember to select the proper abrasive grade for your project.

Aluminum oxide provides a quick initial cut rate. It also performs better on many materials, including high tensile strength alloys. If you are cutting non-metallic materials, however, silicon carbide is the better option.

There are other alternatives, though, including zirconia alumina and ceramic abrasives. These abrasives are designed to provide a fast cut and long-lasting performance.

Inquiry us